Most Popular Products

Textile Machine Yarn Tensioner

MOQ : 50 Units

Textile Machine Yarn Tensioner Specification

- Thermal Conductivity

- Moderate

- NO. Of Hole

- 2

- Automation Grade

- Manual

- Surface Finish

- Corrosion Resistant Plated

- Diameter

- 25 mm (approximate, customizable)

- Capacity

- Suitable for standard yarn tension ranges

- Part Type

- Yarn Tensioner

- Tensile Strength

- High (as per standard steel properties)

- Hardness

- HRC 40-45

- Noise Level

- Low

- Features

- Adjustable tension, long service life, easy installation

- Thread Type

- Metric

- Mounting Type

- Screw Mount

- Size

- Standard (Customizable upon request)

- Product Type

- Textile Machinery Components

- Material

- Steel

- Textile Machine Type

- Winding, Spinning, Reeling, Twisting Machines

- Spare/Component Type

- Yarn Pathway and Tension Control

- Usage

- Industrial

- Speed

- Suitable for high-speed yarn movement

- Dimension (L*W*H)

- 60 x 25 x 18 mm (Approximate)

- Weight

- 120 g

- Warranty

- Yes

Textile Machine Yarn Tensioner Trade Information

- Minimum Order Quantity

- 50 Units

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Textile Machine Yarn Tensioner

Spotlight your textile operations with our masterful Textile Machine Yarn Tensionercrafted for sublime precision and reliability. Featuring a robust coil spring core and an effortless knob or screw adjustment, it delivers phenomenal yarn control across various textile machinery brands. Enjoy instant savings with our ongoing promotion while benefiting from a corrosion-resistant, steel buildguaranteeing a long service life and minimal maintenance. Whether for winding, spinning, or reeling, this tensioner excels in high-speed, industrial environments. Experience optimal tension, reduced noise, and streamlined installation all in one elite component.

Commercial Applications and Material Excellence of Yarn Tensioner

The Textile Machine Yarn Tensioner is expertly engineered for commercial-scale textile operationsideal for winding, spinning, reeling, and twisting machines. Made from corrosion-resistant steel, it ensures long-lasting durability and performs reliably under demanding industrial usage. Its compact, low-noise design and customizable size make it versatile for integration in various application spaces, from large-scale factories to specialized textile workshops. This tensioner optimizes yarn pathway control, maintaining a seamless workflow for high-speed yarn processing endeavors.

Supply Capability, Market Presence, & Sample Policy

We consistently deliver high market value by supplying Textile Machine Yarn Tensioners to leading textile industries across India and international markets. Our supply ability is robust, enabling us to meet bulk orders with short lead times. Competitive list prices ensure accessibility, while a nominal charge secures sample units for evaluation. Our primary domestic market is India, though were well-positioned as a top exporter and supplier abroad, catering to distributors and end-users alike.

Commercial Applications and Material Excellence of Yarn Tensioner

The Textile Machine Yarn Tensioner is expertly engineered for commercial-scale textile operationsideal for winding, spinning, reeling, and twisting machines. Made from corrosion-resistant steel, it ensures long-lasting durability and performs reliably under demanding industrial usage. Its compact, low-noise design and customizable size make it versatile for integration in various application spaces, from large-scale factories to specialized textile workshops. This tensioner optimizes yarn pathway control, maintaining a seamless workflow for high-speed yarn processing endeavors.

Supply Capability, Market Presence, & Sample Policy

We consistently deliver high market value by supplying Textile Machine Yarn Tensioners to leading textile industries across India and international markets. Our supply ability is robust, enabling us to meet bulk orders with short lead times. Competitive list prices ensure accessibility, while a nominal charge secures sample units for evaluation. Our primary domestic market is India, though were well-positioned as a top exporter and supplier abroad, catering to distributors and end-users alike.

FAQs of Textile Machine Yarn Tensioner:

Q: How does the adjustment mechanism of the yarn tensioner function?

A: The adjustment mechanism operates via a knob or screw, allowing precise tension settings to accommodate various yarn types and machine speeds. This ensures accurate yarn control for optimal textile production.Q: What benefits does the coil spring-based yarn tensioner offer over other designs?

A: The precision coil spring delivers consistent tension, prolongs component life, and ensures smooth yarn movement through the machine, resulting in enhanced product quality and reduced downtime.Q: Where can the Textile Machine Yarn Tensioner be installed?

A: It can be installed on various textile machinery, including winding, spinning, reeling, and twisting machines, by using the convenient screw mount and metric thread design.Q: When should maintenance be performed on this tensioner?

A: Only minimal, periodic cleaning is required. Inspect and clean the tensioner at routine intervals based on your facilitys operational schedule to maintain top performance.Q: What is the process for ordering and customizing this yarn tensioner?

A: To order, simply contact our sales team. Customization options, such as size and diameter adjustments, can be discussed to meet your specific textile machinery needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Textile Machine Parts Category

Textile Machine Bobbins

Price 15 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : Yes

Product Type : Textile Machinery Components

Material : Steel

Usage : Industrial

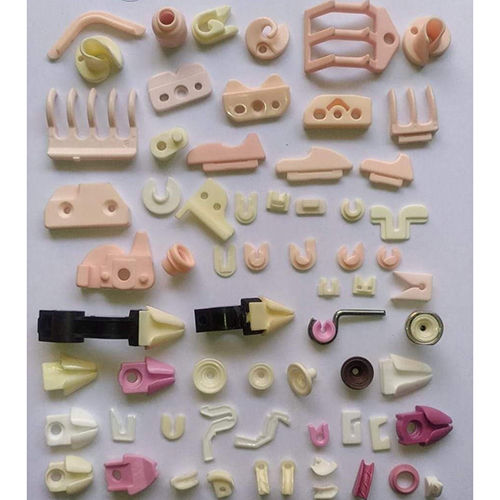

Sewing Machine Parts

Minimum Order Quantity : 50 Units

Warranty : Yes

Product Type : Textile Machinery Components

Material : Steel

Usage : Industrial

Sewing Machine Thread And Yarn Tensioner

Price 200 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : Yes

Product Type : Textile Machinery Components

Material : Steel

Usage : Industrial

Textile Machine Wooden Shuttles

Price 400 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : Yes

Product Type : Textile Machinery Components

Material : Steel

Usage : Industrial

|

Mahakant Industries

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry